The West Virginia Woodturners Association provides woodturners in southeastern West Virginia and western Virginia with an opportunity to meet other turners, enhance their skills, and share their skills and interests in woodturning. Send an email to info@wvwoodturners.com to request additional information about the club and its activities.

Next Meeting - May 16

The May meeting will be on the third Saturday of May since the fourth Saturday falls on Memorial Day weekend. The meeting will begin at 9:30 AM on May 16 at The Fort in Lewisburg. Harry Newman and Bob Nickell will present an introductory pen turning workshop and that will be followed by an advanced pen turning workshop at the July meeting.

April 24 Meeting Highlights

Eighteen members attended the Club's semi-annual wood and tool auction which featured a number of tools and an unusual variety of woods including manzanita and cherry burls, sunshine locust, and alligator juniper. Cliff Baker showed the vacuum adapter and several vacuum chucks that he made. He also explained the formula he uses for pricing bowls that he sells to individuals and shops.

Wood and Tool Auction Treasures

Chain saw, brackets, and bench vise

Wood and a Ring Master

Light, HVLP spray gun, wood>

Show and Tell

Fonzie Fitzwater turned this 8" high maple burl vase.

Gerald Chandler turned this 7" diameter bowl from pecan.

Nelson Dew turned this 10" walnut platter.

John Gregory turned the lidded bowl and cup from osage orange and bead-blasted the lid prior to painting.

Charlie Myers turned this pair of goblets from mimosa.

Charlie also turned a pair of mimosa bracelets.

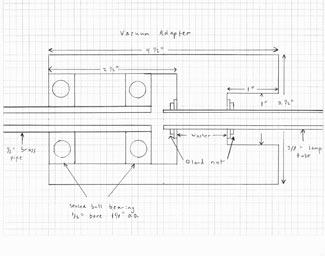

Cliff Baker: Shop-made Vacuum Chuck System

The rotating vacuum adapter is made of a turned housing, 2 sealed ball bearings, a 1/2" brass tube, and a length of 3/8" threaded lamp tube.

The completed vacuum adapter

The vacuum system also includes a vacuum gauge and a needle valve to control the vacuum.

The cherry chuck is attached to the tube with a rubber washer and gland nut. A disc cut from an inner tube is glued to the face of the chuck and conforms to the shape of the turning.

A larger chuck is made from a face plate, plywood disc, 3" PVC pipe coupling, and a rubber disc seal.

When the bowl was rough-turned, the center of the base was marked and is used to accurately align the dried turning so the tenon can be trued prior to final turning.

The tailstock is used to keep the bowl firmly on the vacuum chuck while the majority of the waste is removed with a 3/8" bowl gouge

With the vacuum pump on and a vacuum of at least 20" of mercury, it is safe to remove the tailstock and carefully turn away the remaining nub and finish the base.

John Gregor made this vacuum chuck using Oogloo silicone rubber.

It is always a challenge to design a vacuum chuck with a reliable way to seal the workpiece to the chuck. John Gregor found the solution to that problem in the April 2013 AAW journal that describes casting a seal made of Oogloo, a type of silicone rubber. If you google "oogloo silicone" you will get several references for making the material.

This material is very easy and inexpensive to make. Mix 4 parts by volume silicone caulk I with 1 part naphtha to form a viscous liquid. Then add 2 parts corn starch and mix well until all the corn starch has been combined with the silicone. The mixture is then pured into a mold surrounding the chuck and after a half hour, the silicone has cured and the chuck can be removed from the mold. The silicone is soft and will form a tight seal with the bowl and will not leave marks or change the color of the wood.

Cliff Baker: Pricing Formula

Cliff has developed a formula for calculating the retail price of a bowl that incorporates the value of the wood and the time spent in turning and finishing the bowl. He turned a number of bowls of diferent sizes and styles with both flat and natural edge and took careful notes on the time needed for each step. Most of his sales are to individual customers with prices ranging from $50 for 6" bowls to $150 for 12"bowls. Some sales are made through shops that charge a 30-40% commission.

The basic formula is Price = wood value * grain factor + sanding&finishing labor * style * form * quality

- grain factor: crotch, burl, spalted, curly, etc (1 to 3)

- form: natural edge, bark, enclosed form, knot holes, etc (1.0 - 1.5)

- style: add .1 for each intersecting surface (1.0 - 1.2)

- quality: flawed finish, sanding marks, abrupt change of curve, feel (0.8 - 1.0)

The formula values wood at $6.00 a board foot and labor at $15.00 an hour. The reults are usually too low for small bowls and too large for large bowls.

After the target price is calculated, he always aks this question: "Am I comfortable buying or selling the bowl at that price?" If the answer is no, the price is adjusted accordingly.

Turner's Shop

The Turner's Shop this month featuresGerald Chandler. While we have all visited his shop when he hosted the monthly meetings, his equipment and projects have been relegated to the backgound. With this feature, Gerald shows off his his turnings and his tools.

Lathes and Lasagna

Lathes and Lasagna sessions are temporarily suspended since Bill is in the process of moving his shop.

General Club Information

For further information about any WVWA activity, call Bill Sproul at (304) 497-2319.

Supporting Companies

We would like to thank these companies for the support they have provided to the Club during the past year. Check out their websites when you are ready to purchase products that they stock.

Craft Supplies USA is a one-stop shopping site for everything a wood turner might need or want - lathes, tools, accessories, project supplies, materials, and more.

Woodcraft offers a 10% discount at the Roanoke store to WVWA members when they show a current membership card.

by WVWA, a chapter of the American Association of Woodturners