Wooden Threads: November 17, 2012

Jim Meyer demonstrated several different ways that both internal and external threads can be cut on turned objects

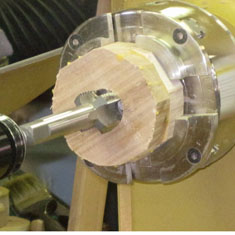

Tap and Faceplate

Tapping

The simplest way to cut threads is to use a tap. The Beall Tool Co. offers taps that match the most common spindle threads. A low-cost faceplate is made by gluing several blocks together to make a blank slightly thicker than the length of the spindle. A hole 1/8" smaller than the spindle is bored through the blank. The tailstock keeps the tap centered and the tap is rotated with a wrench to cut the threads.

Cut threads all the way through the faceplate - do not remove the tap by rotating it in the reverse direction since that will damage the threads. The faceplate is glued to the turning blank and threaded onto the spindle. After turning is complete, the faceplate can be parted off or sawed off.

Router Accessory

Threading a Dowel

The Beall Tool Co. also makes an accessory for cutting external threads with a small router or laminate trimmer. A veining bit whose profile matches the standard thread profile is mounted in the router and a blank dowel is pushed into the jig. The jig has a guide that controls the pitch of the thread while the depth of the thread is controlled by the depth adjustment of the router bit.

Thread Chasing Tools

Freehand Chasing

Robert Sorby makes tools for chasing internal and external threads with 10, 16 and 20 threads per inch. Once the blank has been prepared and a relief cut has been made at the end of the threaded area, the tool is held lightly and brought into contact with the rotating workpiece. In order to cut threads cleanly, the tool must be allowed to advance the distance between adjacent threads for each revolution of the spindle. Needless to say, this becomes more difficult as the speed increases.

Sorby offers this advice: "Threading is a skill which needs practice – it does not come automatically. We recommend that for your first venture in threading you should select a finer thread size (16 or even better 20 tpi). "

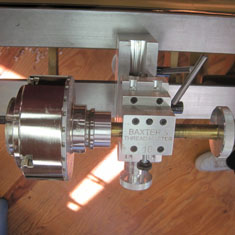

Baxter Threadmaster

Advancing the Workpiece

The Baxter Threadmaster is made by the Best Wood Tools and is a high-end accessory (about $500) that allows internal and external threads to be accurately milled on a lathe. A cutter is mounted on the headstock spindle and the Threadmaster takes the place of the tailstock. A standard chuck mounts on the spindle of the Threadmaster and a handwheel allows the chuck and workpiece to move along the axis of the lathe in the same way that a live center is moved by the tailstock. The pitch of the handwheel controls the pitch of the threads.

The Threadmaster allows the chuck to be moved in and out to match the diameter of the workpiece to be threaded. The chuck and workpiece can also be moved up and down to control the depth of the threads.

Once the chuck and workpiece have been properly positioned, the lathe is turned on and the cutter is run at about 2000 rpm. The handwheel is manually rotated which rotates the workpiece and advances it allowing threads to be cleanly cut at the pitch of the handwheel.

by WVWA, a chapter of the American Association of WoodturnersReturn to the Events page